Technology

The high capacity of our plant, advanced technology, and efficiency of our machinery and equipment places Tana Drilling and Industries Plc as the leader in Ethiopia. Furthermore, it gives us the ability to equal the combined capacity of all the other plastic manufacturing industries in the country, with an annual capacity of more than 30,000 tons. Our capacity is expected to exceed 50,000 MT within the next two years. All of this will be accomplished with the support of our laboratory, which utilizes the latest and highest precision testing equipment from a world renowned German manufacturer and can also serve other industries in the field.

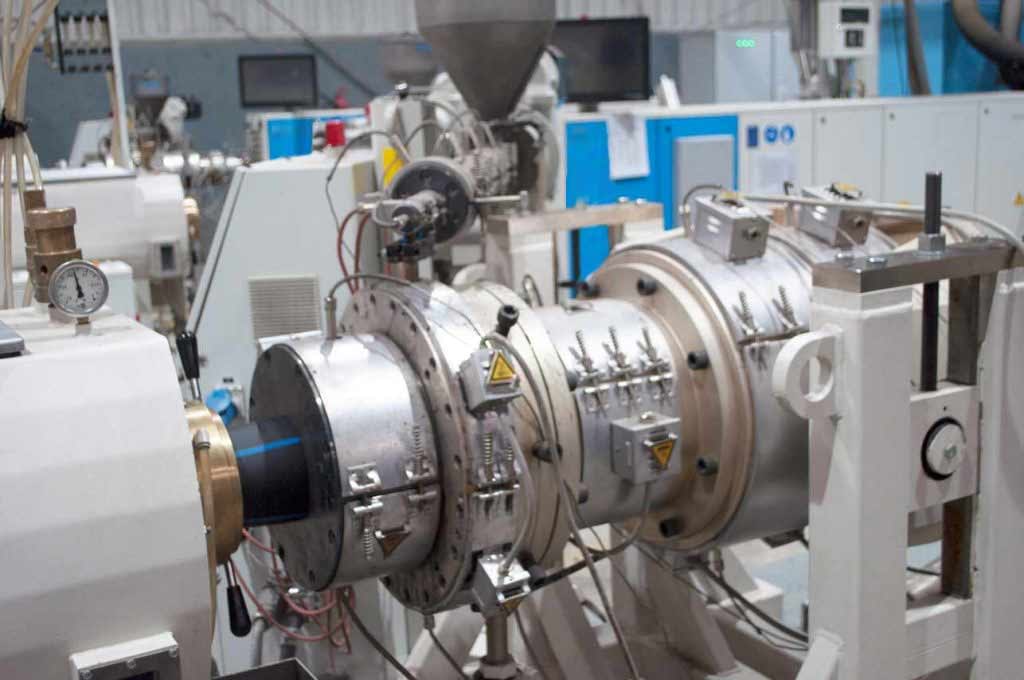

High Capacity & Quality Extrusion

The pipes production line of TDI consists of seven extrusion lines from Krauss Maffei of Germany, with a total capacity of 4,600 kg/h and 100% efficiency (guaranteed by the supplier). All seven extrusion lines are fitted with Programmable Logic Controllers and equipped with automatic material handling system, which serves as a dosing, mixing and conveying system.

Laboratory Equipment

TDI’s HDPE and PVC pipes are subject to strict quality control programs for monitoring. Before being released for production use, incoming materials are tested to ensure that they meet standard criteria. In addition, the pipes production process and finished goods are guaranteed to be of the highest quality.

Raw Materials Dryers

TDI has also invested in a system for drying the polyethylene raw materials. Our system is dust free and preheats the polyethylene granules before they are processed in the extrusion equipment. The polyethylene raw material, which is currently imported from abroad, absorbs moisture while in transit to our factory.

Chillers

The factory has two high capacity, outdoor, air cooled chillers. Each has a cooling capacity of 630MW and is equipped with process cooling rigs with spare pumps and other necessary attachments.